Keyways may look like small, simple features, but they play a huge role in the smooth operation of countless mechanical systems. From electric motors to gearboxes, pulleys, pumps, and drive hubs, keyways ensure that torque is transferred reliably and safely between rotating components. Behind every precisely cut keyway is a keyway broach—a tool engineered to deliver accuracy, consistency, and clean finishes in a single stroke. But with so many sizes, styles, and configurations available, choosing the right keyway broach can feel overwhelming. The right tool will elevate production quality and efficiency, while the wrong one can cause downtime, poor fits, and unnecessary wear. Understanding the factors that influence your choice is the first step toward making a confident, future-ready decision.

Understanding the Role of Keyway Broaches in Modern Manufacturing

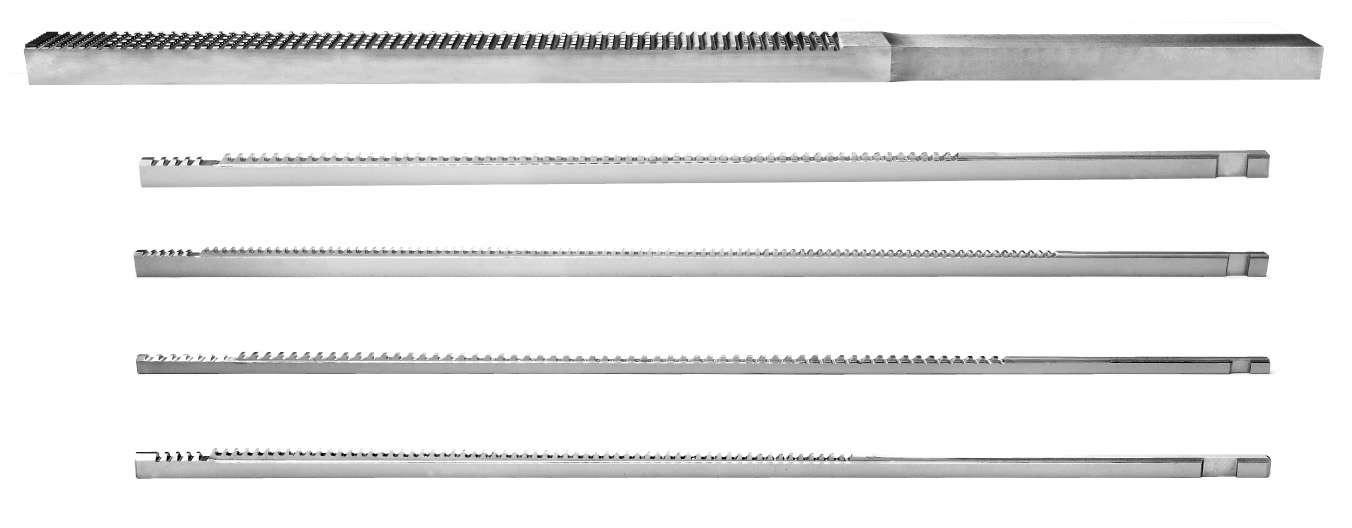

A keyway broach is designed to remove material progressively to create a slot inside a gear, pulley, bushing, or similar component. Its stepped teeth cut the profile to the precise width and depth needed for the key that will lock two rotating parts together. Because broaching completes this internal feature in one pass, it is far faster and more consistent than milling, shaping, or EDM for high-volume work.

Keyway broaches are used across automotive, aerospace, industrial machinery, and heavy equipment manufacturing—anywhere strong, aligned, torque-transmitting connections are required. Their ability to hold tight tolerances makes them essential for components that must mate perfectly with shafts and keys. When selecting the right broach for your operation, it is crucial to consider not only the shape and size of the keyway but also the material being machined, the expected production volume, and the limitations of your broaching machine.

Matching Broach Size and Style to Your Application

The size of the keyway broach is determined by the width and depth of the keyway you need to cut, which in turn must match the key and shaft dimensions. Even a small mismatch can result in vibration, slippage, or misalignment once the component is in use. To avoid this, manufacturers must consult the standard keyway sizing charts that correlate shaft diameters with proper keyway dimensions. A broach that is even slightly under or oversized can compromise the functionality and lifespan of the final assembly.

Beyond size, the style of broach matters significantly. Most keyway broaches are either the standard “A,” “B,” or “C” series, each designed with specific cross-section thicknesses and tolerances that work with compatible bushings. Using the wrong series can lead to improper seating, deflection during cutting, or irreversible tool wear. Manufacturers must match the broach series not just to the keyway requirements but also to the machine’s stroke, pull capacity, and bushing compatibility.

The Importance of Bushings and Guide Alignment

A keyway broach does not work alone. It relies on a bushing to guide the tool through the part, keeping it aligned and ensuring that the cut is straight and consistent from start to finish. The bushing must match both the external diameter of the workpiece and the internal slot geometry required for the broach. If the bushing is even slightly misaligned, the broach can lean to one side, producing tapered or uneven keyways that will not mate correctly.

Choosing the right combination of broach and bushing is therefore essential. When manufacturers invest in high-precision bushings made from hardened, wear-resistant materials, they often notice substantial improvements in tool life and dimensional repeatability. This pairing is especially important when working with hard metals like stainless steel or alloy steels, where the forces exerted during broaching are significantly higher.

Considering Material and Tool Durability

The material you are cutting plays a major role in selecting the right keyway broach. Softer materials like aluminium or brass are relatively easy to broach and cause minimal tool wear. Harder materials, such as carbon steel, alloy steel, and certain stainless steels, demand broaches made from premium tool steels or coated with wear-resistant finishes. Using the wrong broach for a hard material can shorten tool life dramatically and compromise surface finish.

Tool durability becomes even more critical in high-volume production settings. A broach that wears too quickly will introduce dimensional inconsistencies and increase downtime for sharpening or replacement. Manufacturers looking to optimise cost efficiency must assess tool life expectations from the start. Investing in higher-grade broaches may cost more upfront, but the extended lifespan and superior performance often make it a worthwhile long-term investment.

Aligning Broach Selection With Production Volume

Production volume is one of the most overlooked—but most important—factors in choosing the right keyway broach. For small-scale or custom work, a general-purpose broach may be sufficient. But high-volume manufacturing demands tools engineered for repeatability, resilience, and minimal maintenance. If your operation requires thousands of identical keyways, selecting a broach designed for heavy-duty, repetitive cutting is essential for maintaining quality and efficiency.

Manufacturers should also consider the frequency of re-sharpening. Broaches used in large production runs will inevitably need maintenance, and choosing a tool with geometry that can be sharpened multiple times without losing dimensional integrity offers significant long-term advantages.

Selecting the right keyway broach is not just about choosing a tool—it’s about safeguarding the precision, performance, and reliability of the products you create. By understanding the relationship between broach size, material compatibility, guide bushings, machine capacity, and production goals, manufacturers can make informed decisions that enhance both quality and productivity. A well-chosen keyway broach becomes more than a cutting tool; it becomes a cornerstone of efficient, dependable manufacturing.